Automation by the Hour

at 50% of the human wage

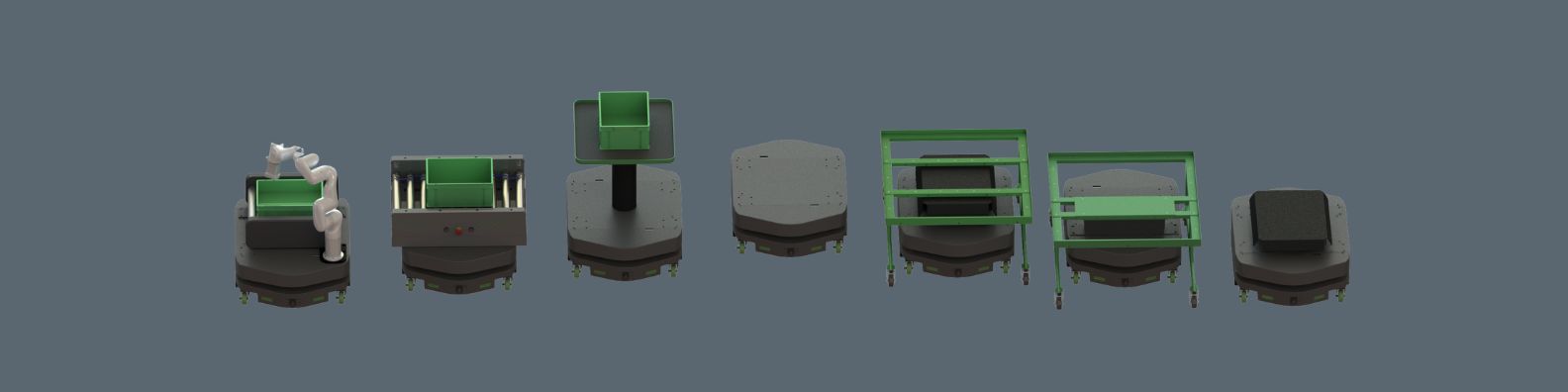

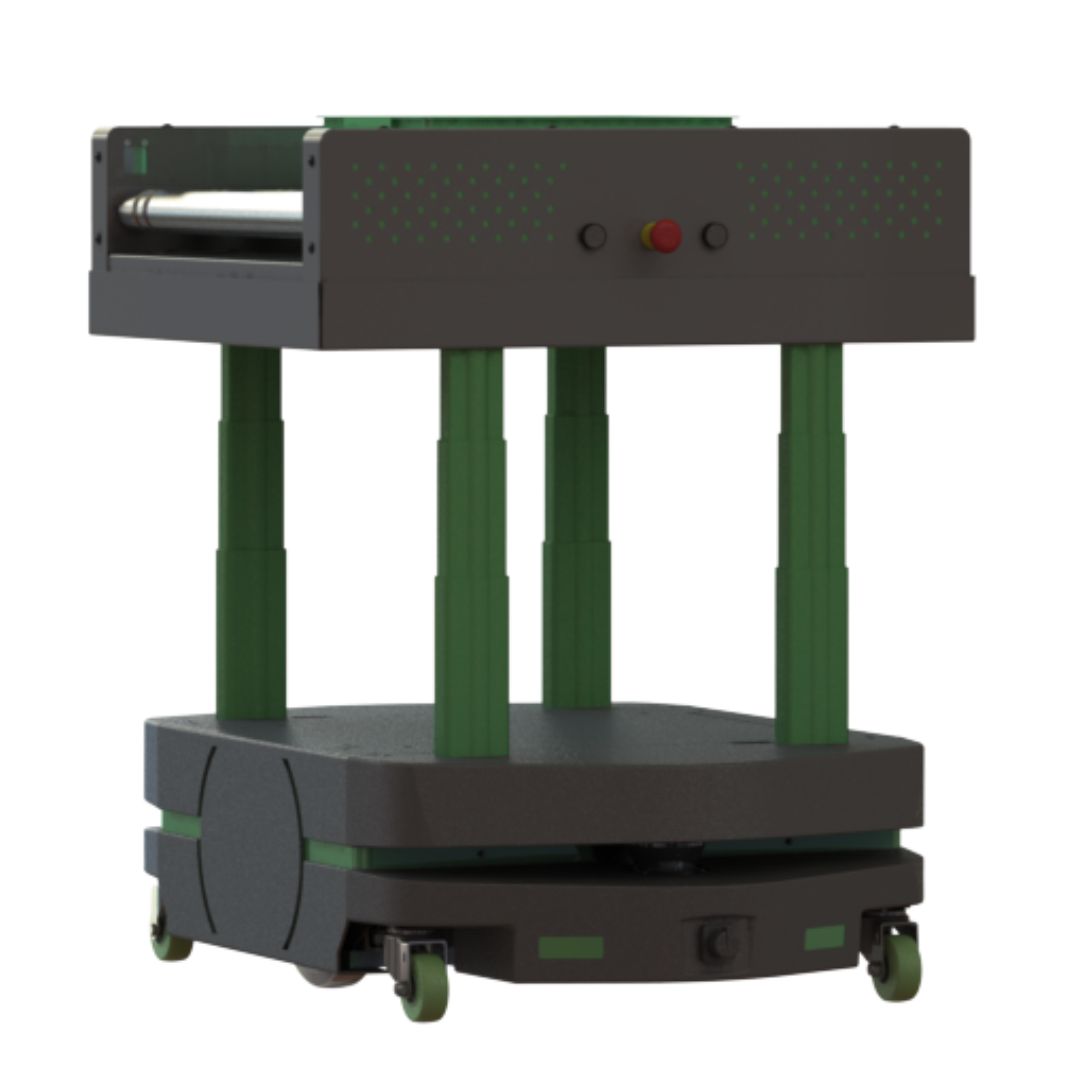

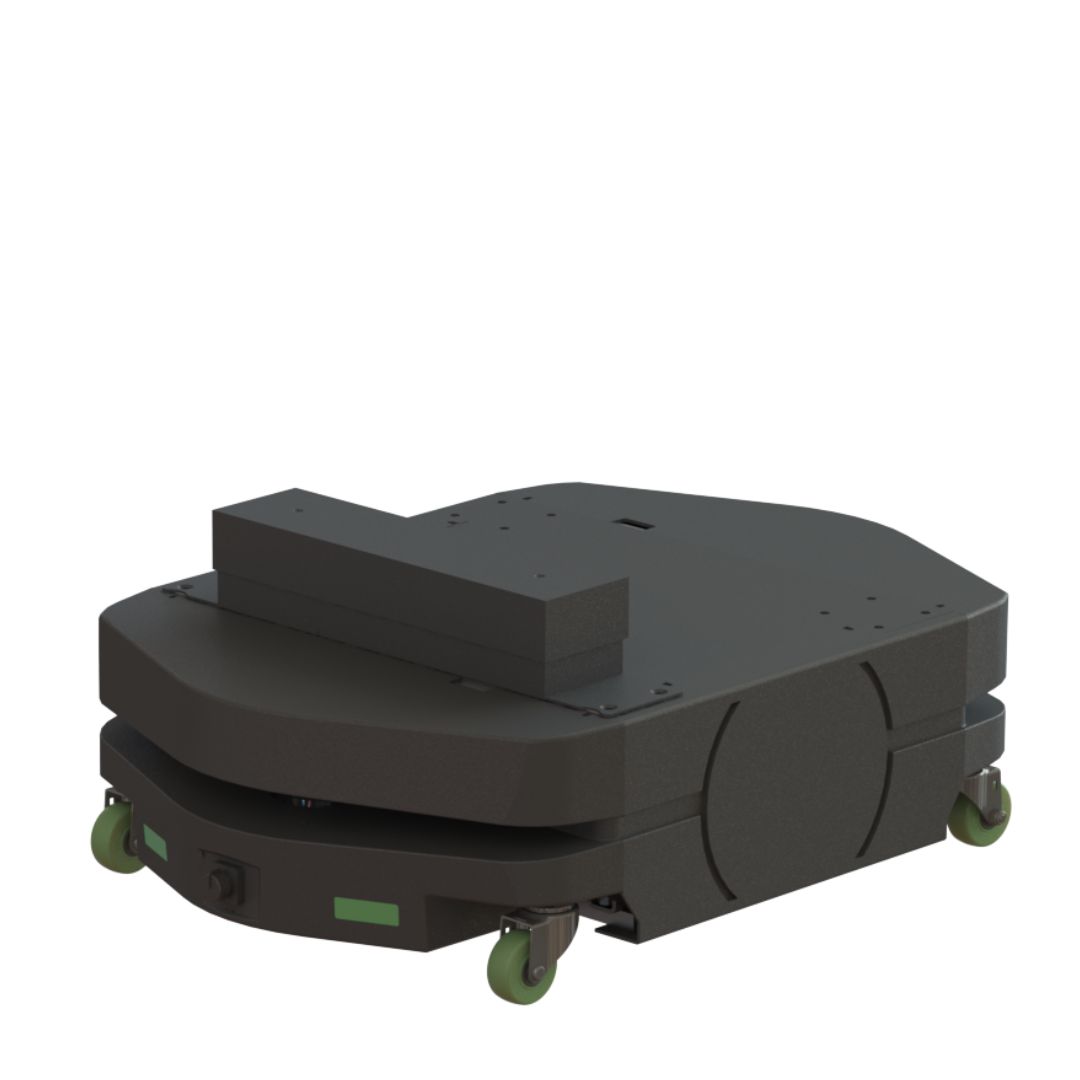

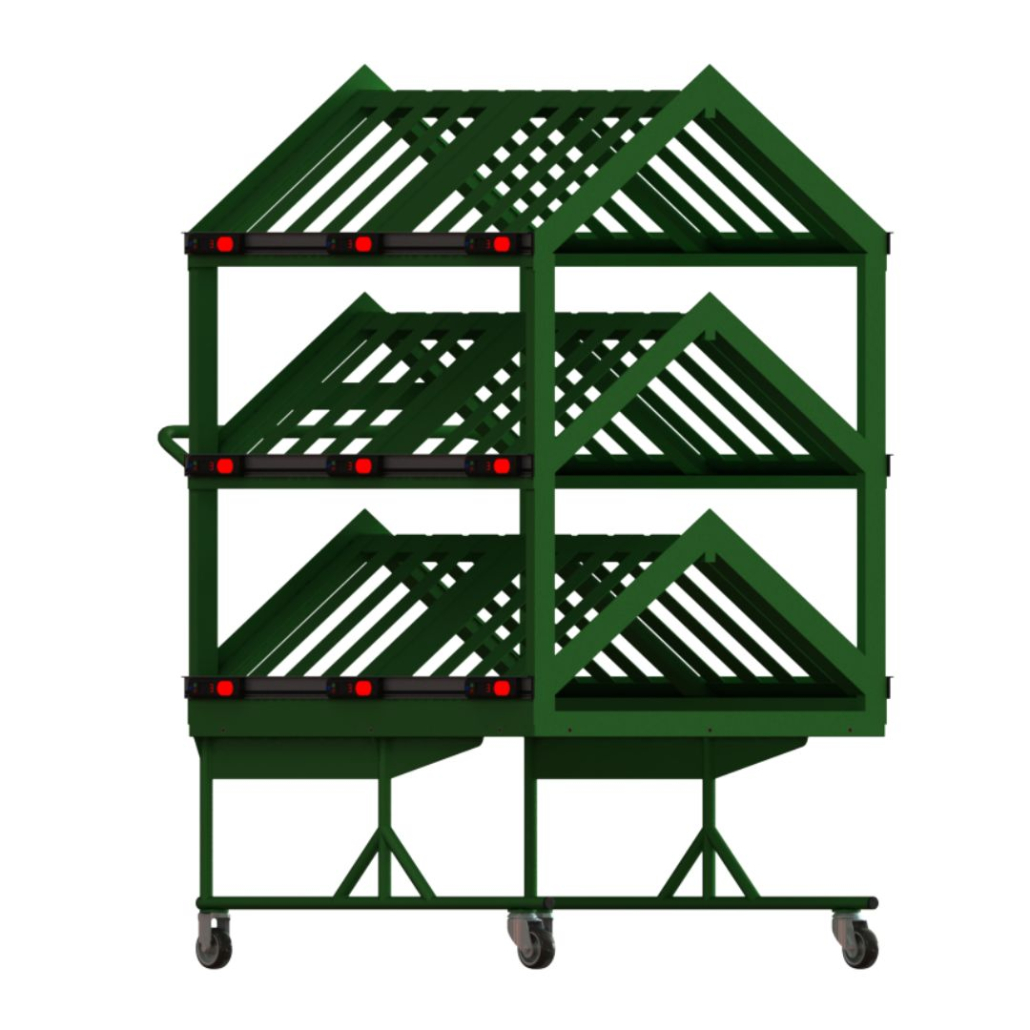

Put robot vehicles to work in your operation—on your terms. Autonomous GO is a fully managed, pay-by-the-hour automation service that delivers real productivity without upfront investment or disruption.

We supply, set up, and support robot workers that handle material movement efficiently and consistently – so your skilled team can focus on higher-value work.

There are no capital costs, no installation or licence fees, and no long contracts—just a scalable service that adapts to your needs, whether seasonal or continuous. You’re invoiced monthly based only on the hours worked, with the flexibility to stop at any time with 30 days’ notice. Everything is monitored and supported by our team of experts to ensure consistent performance.

Stop carrying the load. Let automation do the heavy lifting.